UC Merced Student Housing

Project Details

| Location: | Merced, CA |

|---|---|

| Region: | Northern California |

| Owner: | University of California |

| GC: | ProWest Constructors |

| Engineer: | GFDS San Francisco |

| Architect: | EHDD Architecture |

| Steel Fabricator: | ConXtech Manufacturing |

| Steel Erector: | Bragg Crane & Rigging |

| ConXtech Scope: | Structural Steel, Decking |

“This was the smoothest structural system I’ve ever erected in my 30 years of being an ironworker.”

“The ConX stair system was the easiest stair system I’ve ever installed.”

Project Narrative

The UC Merced Housing 4: The Summits project consists of a five-story, 364 bed, 110,000 square foot Student Housing Facility. This project utilized BIM integration and clash management by communicating in a collaborative 3D environment while sharing models amongst trades for individual discipline fabrication. Models in .ifc format were imported into Tekla BIMsight and reviewed at weekly collaboration meetings. Further clash prevention was accomplished in Navisworks Manage via output from Tekla Structures, where in-model tasks were easily assigned to further investigate before the next gathering.

ConXtech Manufacturing utilized all-automated modular detailed connections, shop drawing production, electronic BOMs and nesting, and CNC information. Additionally, data output from Tekla Structures allowed for sophisticated MRP program utilization in manufacturing and field assembly environment.

ConX Solutions

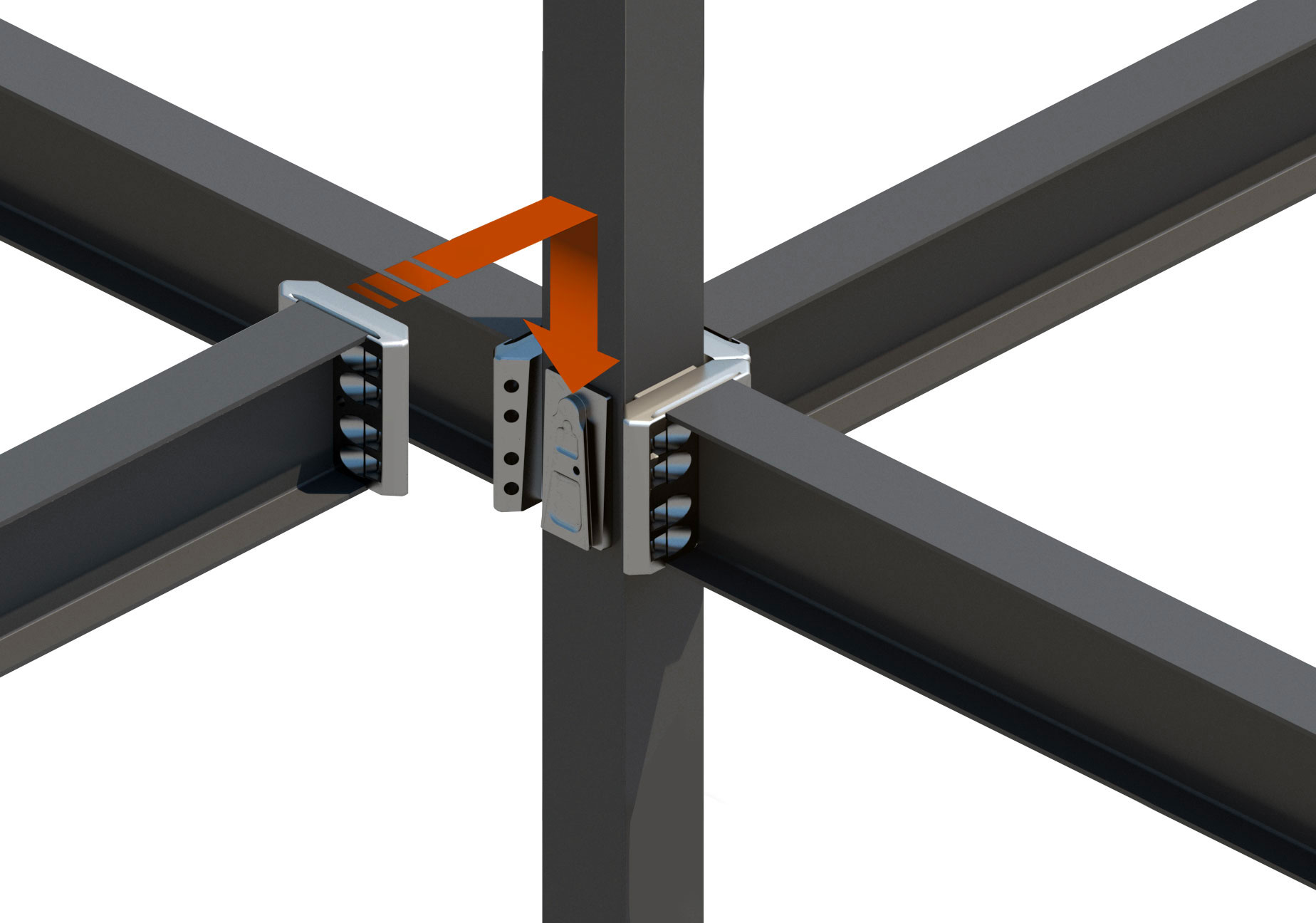

ConXtech subcontracted Dowco Consultants Ltd. to provide detailing services for the first time. Typically it takes valuable resources to teach detailing firms company-specific processes and procedures, but we were able to efficiently implement ConXtech’s standard part database via pre-programmed, auto-connecting components, thus allowing for more effective non-core component modeling. Dowco was able to use ConXtech’s custom components and Tekla API extensions to rapidly build and connect the model. Due to the fact that the ConXR system utilizes all HSS 8×8 columns, W12 beams, and standard moment and gravity shear connections – detailing setup, connection design, and connection application in the model was significantly simplified and faster compared to traditional steel detailing projects.

Very rewarding was the relationship between ConXtech and ConX Certified Erector, Bragg Crane and Rigging. Being the first project the team collaborated on, an initial learning curve was expected with respect to ConX Lower & Locking™ prefababricated connections, just-in-time fabrication and delivery, and field drawing standards. However, utilizing home-grown tools such as ConXtech’s Planned Shipping Attribute Import, the team was able to pre-plan daily work packages for the erector to assemble. This flowed upstream, importing into ConXtech’s MRP system, which dictated fabrication sequencing and, in turn, planned overall labor resource requirements. This combined with benefits of Tekla Structures, such as the option to use BIMsight in the field for quick visual planning, helped contribute to Bragg’s overall schedule savings while erecting the structure at an astonishing 120 to 160 pieces per day.